33,000 Books Line The Walls In The Wine Library At The Boutique Hotel & Spa, Zurich

33,000 books line the walls in the Wine Library at the Boutique Hotel & Spa, Zurich

More Posts from Smparticle2 and Others

“People who never met her except across the footlights did not realize how, in her private life, she had such compassion and interest in everyone. After I returned from Hong Kong I was ill with a virus and she rang me up reproachfully later to say, ‘Why didn’t you let me know? I would have come and sit with you.’ Giving flowers to sick people is easy. Giving that precious commodity time is far more expensive for someone who had such a full life. But she always found time for everyone.” -Godfrey Winn

“She has autonomy. She has a strong will. But she can’t move. So in many ways her life is my life. It’s bigger than me, it controls me, and it makes me fight like never before. We spend so much time together that she’s a part of me. She knows how important she is to me. She had childhood cancer. Her heart failed three times. And I was by her side the entire time. I never realized that I could love someone as much as this. She could never hurt me. She could never hurt anyone. We always ask her: ‘Are you angry?’, ‘Are you mad?’ And she always says ‘no.’ She laughs when I laugh. And right now I’m trying not to cry. Because she’ll cry if I cry.” (São Paulo, Brazil)

Zillertal Alps // Tom Klocker

The Beauty of Webb Telescope’s Mirrors

The James Webb Space Telescope’s gold-plated, beryllium mirrors are beautiful feats of engineering. From the 18 hexagonal primary mirror segments, to the perfectly circular secondary mirror, and even the slightly trapezoidal tertiary mirror and the intricate fine-steering mirror, each reflector went through a rigorous refinement process before it was ready to mount on the telescope. This flawless formation process was critical for Webb, which will use the mirrors to peer far back in time to capture the light from the first stars and galaxies.

The James Webb Space Telescope, or Webb, is our upcoming infrared space observatory, which will launch in 2019. It will spy the first luminous objects that formed in the universe and shed light on how galaxies evolve, how stars and planetary systems are born, and how life could form on other planets.

A polish and shine that would make your car jealous

All of the Webb telescope’s mirrors were polished to accuracies of approximately one millionth of an inch. The beryllium mirrors were polished at room temperature with slight imperfections, so as they change shape ever so slightly while cooling to their operating temperatures in space, they achieve their perfect shape for operations.

The Midas touch

Engineers used a process called vacuum vapor deposition to coat Webb’s mirrors with an ultra-thin layer of gold. Each mirror only required about 3 grams (about 0.11 ounces) of gold. It only took about a golf ball-sized amount of gold to paint the entire main mirror!

Before the deposition process began, engineers had to be absolutely sure the mirror surfaces were free from contaminants.

The engineers thoroughly wiped down each mirror, then checked it in low light conditions to ensure there was no residue on the surface.

Inside the vacuum deposition chamber, the tiny amount of gold is turned into a vapor and deposited to cover the entire surface of each mirror.

Primary, secondary, and tertiary mirrors, oh my!

Each of Webb’s primary mirror segments is hexagonally shaped. The entire 6.5-meter (21.3-foot) primary mirror is slightly curved (concave), so each approximately 1.3-meter (4.3-foot) piece has a slight curve to it.

Those curves repeat themselves among the segments, so there are only three different shapes — 6 of each type. In the image below, those different shapes are labeled as A, B, and C.

Webb’s perfectly circular secondary mirror captures light from the 18 primary mirror segments and relays those images to the telescope’s tertiary mirror.

The secondary mirror is convex, so the reflective surface bulges toward a light source. It looks much like a curved mirror that you see on the wall near the exit of a parking garage that lets motorists see around a corner.

Webb’s trapezoidal tertiary mirror captures light from the secondary mirror and relays it to the fine-steering mirror and science instruments. The tertiary mirror sits at the center of the telescope’s primary mirror. The tertiary mirror is the only fixed mirror in the system — all of the other mirrors align to it.

All of the mirrors working together will provide Webb with the most advanced infrared vision of any space observatory we’ve ever launched!

Who is the fairest of them all?

The beauty of Webb’s primary mirror was apparent as it rotated past a cleanroom observation window at our Goddard Space Flight Center in Greenbelt, Maryland. If you look closely in the reflection, you will see none other than James Webb Space Telescope senior project scientist and Nobel Laureate John Mather!

Learn more about the James Webb Space Telescope HERE, or follow the mission on Facebook, Twitter and Instagram.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com.

Your blog is super cool! I have a few questions. How do you get your equipment and chemicals to carry out your experiments? I was just wondering as I'd like to start doing experiments at home. What would be a good experiment to start with also? Sorry if you have already answered these questions

Hey, thanks for the kind words! This is going to be a long answer! Let’s start with equipment:

Keep reading

Irving Langmuir, who won the 1932 Nobel Prize for ‘Surface Chemistry’, demonstrates how dipping an oil-covered finger into water creates a film of oil, pushing floating particles of powder to the edge.

The same phenomenon can be used to power a paper boat with a little ‘fuel’ applied to the back: as the film expands over the water, the boat is is propelled forward:

With experiments like this he revealed that these films are just one molecule thick - a remarkable finding in relation to the size of molecules.

In the full archive film, Langmiur goes on to demonstrate proteins spreading in the same way, revealing the importance of molecular layering for structure.

First, he drops protein solution onto the surface, and it spreads out in a clear circle, with a jagged edge:

Add a little more oil on top, and a star shape appears:

By breaking it up further, he makes chunks of the film which behave like icebergs on water:

You can watch the full demonstrations, along with hours more classic science footage, in our archive.

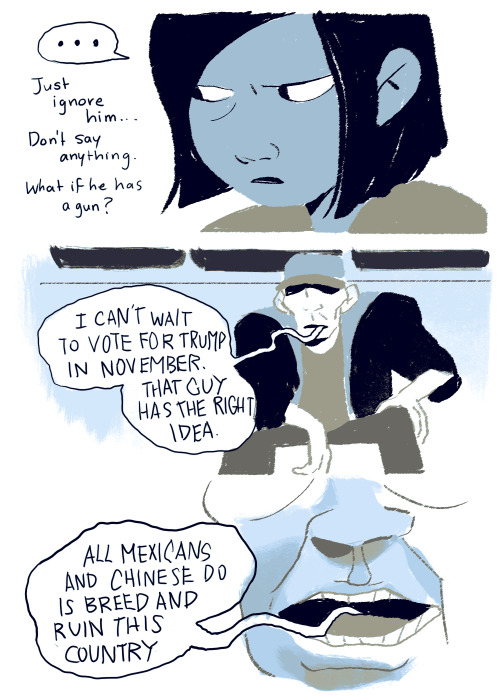

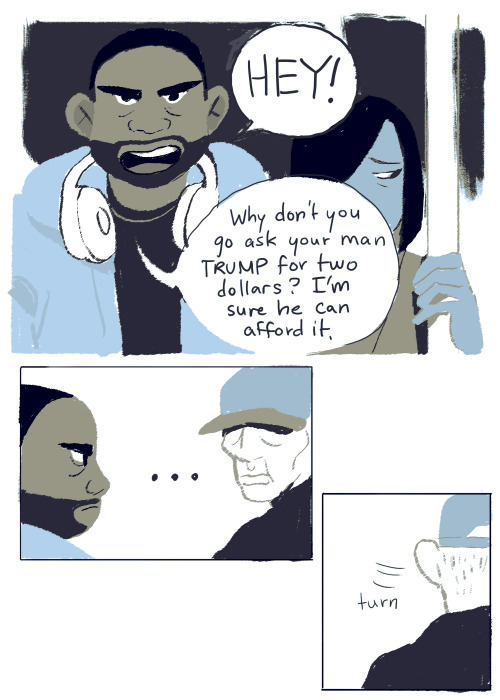

It’s been an emotional week. I wanted to share this encounter I had with a very hateful man on the Pittsburgh bus because it reminds me that there are brave people in this world. Let’s all do everything we can to stand up for each other.

Self-assembling particles brighten future of LED lighting

Just when lighting aficionados were in a dark place, LEDs came to the rescue. Over the past decade, LED technologies – short for light-emitting diode – have swept the lighting industry by offering features such as durability, efficiency and long life.

Now, Princeton engineering researchers have illuminated another path forward for LED technologies by refining the manufacturing of light sources made with crystalline substances known as perovskites, a more efficient and potentially lower-cost alternative to materials used in LEDs found on store shelves.

The researchers developed a technique in which nanoscale perovskite particles self-assemble to produce more efficient, stable and durable perovskite-based LEDs. The advance, reported January 16 in Nature Photonics, could speed the use of perovskite technologies in commercial applications such as lighting, lasers and television and computer screens.

“The performance of perovskites in solar cells has really taken off in recent years, and they have properties that give them a lot of promise for LEDs, but the inability to create uniform and bright nanoparticle perovskite films has limited their potential,” said Barry Rand an assistant professor of electrical engineering and the Andlinger Center for Energy and the Environment at Princeton.

Read more.

Studio Ghibli + Food

-

arewealloststars liked this · 4 weeks ago

arewealloststars liked this · 4 weeks ago -

afrotumble liked this · 1 year ago

afrotumble liked this · 1 year ago -

diocekerdilu liked this · 1 year ago

diocekerdilu liked this · 1 year ago -

tomandonotaque liked this · 1 year ago

tomandonotaque liked this · 1 year ago -

teenagevoidathletewagon liked this · 2 years ago

teenagevoidathletewagon liked this · 2 years ago -

caspertheghostguy liked this · 2 years ago

caspertheghostguy liked this · 2 years ago -

bluecricket21 reblogged this · 2 years ago

bluecricket21 reblogged this · 2 years ago -

bluecricket21 liked this · 2 years ago

bluecricket21 liked this · 2 years ago -

oxfordsonnets liked this · 2 years ago

oxfordsonnets liked this · 2 years ago -

z-bot reblogged this · 2 years ago

z-bot reblogged this · 2 years ago -

tomblr1895 reblogged this · 2 years ago

tomblr1895 reblogged this · 2 years ago -

dawn9476 reblogged this · 2 years ago

dawn9476 reblogged this · 2 years ago -

fleurdeneuf reblogged this · 3 years ago

fleurdeneuf reblogged this · 3 years ago -

solosepensi liked this · 4 years ago

solosepensi liked this · 4 years ago -

truesoulx liked this · 4 years ago

truesoulx liked this · 4 years ago -

hermionegrangerislifegoals reblogged this · 4 years ago

hermionegrangerislifegoals reblogged this · 4 years ago -

haleylightwood liked this · 4 years ago

haleylightwood liked this · 4 years ago -

thecutestwonders reblogged this · 4 years ago

thecutestwonders reblogged this · 4 years ago -

goloveforever2000things liked this · 4 years ago

goloveforever2000things liked this · 4 years ago -

blackbirdinthebox liked this · 4 years ago

blackbirdinthebox liked this · 4 years ago -

abbys-little-whippersnapper reblogged this · 4 years ago

abbys-little-whippersnapper reblogged this · 4 years ago -

abbys-little-whippersnapper liked this · 4 years ago

abbys-little-whippersnapper liked this · 4 years ago -

natas-golden-stallion reblogged this · 4 years ago

natas-golden-stallion reblogged this · 4 years ago -

moniferi25 liked this · 5 years ago

moniferi25 liked this · 5 years ago -

moniferi25 reblogged this · 5 years ago

moniferi25 reblogged this · 5 years ago -

hazybee liked this · 5 years ago

hazybee liked this · 5 years ago -

studylikeasnek reblogged this · 5 years ago

studylikeasnek reblogged this · 5 years ago -

missfluffystein liked this · 5 years ago

missfluffystein liked this · 5 years ago -

fiftycookies liked this · 5 years ago

fiftycookies liked this · 5 years ago -

marbearishere reblogged this · 5 years ago

marbearishere reblogged this · 5 years ago -

studentofthecosmos reblogged this · 5 years ago

studentofthecosmos reblogged this · 5 years ago -

elemmirekirk5031 liked this · 5 years ago

elemmirekirk5031 liked this · 5 years ago -

marbearishere liked this · 5 years ago

marbearishere liked this · 5 years ago -

risetomars reblogged this · 5 years ago

risetomars reblogged this · 5 years ago