Sunday’s Are For Relaxing With A Good Book.

Sunday’s are for relaxing with a good book.

More Posts from Smparticle2 and Others

First and last appearances.

Juliet - Marshall Beach, San Francisco

Follow the Ballerina Project on Facebook, Instagram, YouTube, Twitter & Pinterest

For information on purchasing Ballerina Project limited edition prints

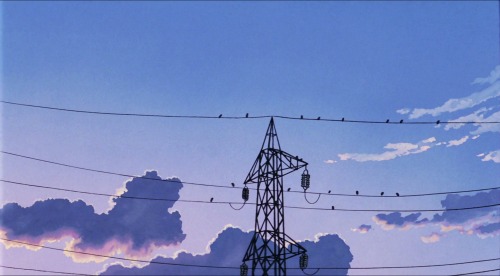

All these beautiful scenes and all I could think was "LOOK AT ALL THE SCATTERING" :')

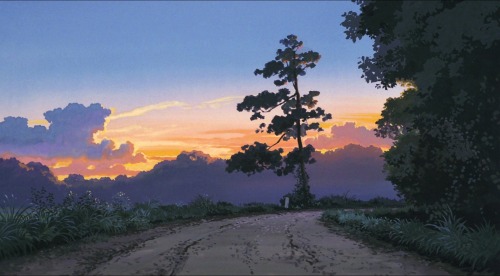

More Art of My Neighbor Totoro - Art Direction by Kazuo Oga (1988)

Novel laminated nanostructure gives steel bone-like resistance to fracturing under repeated stress

Metal fatigue can lead to abrupt and sometimes catastrophic failures in parts that undergo repeated loading, or stress. It’s a major cause of failure in structural components of everything from aircraft and spacecraft to bridges and powerplants. As a result, such structures are typically built with wide safety margins that add to costs.

Now, a team of researchers at MIT and in Japan and Germany has found a way to greatly reduce the effects of fatigue by incorporating a laminated nanostructure into the steel. The layered structuring gives the steel a kind of bone-like resilience, allowing it to deform without allowing the spread of microcracks that can lead to fatigue failure.

The findings are described in a paper in the journal Science by C. Cem Tasan, the Thomas B. King Career Development Professor of Metallurgy at MIT; Meimei Wang, a postdoc in his group; and six others at Kyushu University in Japan and the Max Planck Institute in Germany.

“Loads on structural components tend to be cyclic,” Tasan says. For example, an airplane goes through repeated pressurization changes during every flight, and components of many devices repeatedly expand and contract due to heating and cooling cycles. While such effects typically are far below the kinds of loads that would cause metals to change shape permanently or fail immediately, they can cause the formation of microcracks, which over repeated cycles of stress spread a bit further and wider, ultimately creating enough of a weak area that the whole piece can fracture suddenly.

Read more.

Packing numerous books and papers that he plans to read over winter break, the grad student deludes himself.

Good vibrations no longer needed for speakers as research encourages graphene to talk

A pioneering new technique that encourages the wonder material graphene to “talk” could revolutionise the global audio and telecommunications industries.

Researchers from the University of Exeter have devised a ground-breaking method to use graphene to generate complex and controllable sound signals. In essence, it combines speaker, amplifier and graphic equaliser into a chip the size of a thumbnail.

Traditional speakers mechanically vibrate to produce sound, with a moving coil or membrane pushing the air around it back and forth. It is a bulky technology that has hardly changed in more than a century.

This innovative new technique involves no moving parts. A layer of the atomically thin material graphene is rapidly heated and cooled by an alternating electric current, and transfer of this thermal variation to the air causes it to expand and contract, thereby generating sound waves.

Read more.

There is a time when it is necessary to abandon the used clothes, which already have the shape of our body and to forget our paths, which takes us always to the same places. This is the time to cross the river: and if we don’t dare to do it, we will have stayed, forever beneath ourselves

Fernando Pessoa (via paizleyrayz)

-

bluemann reblogged this · 6 years ago

bluemann reblogged this · 6 years ago -

milydiadeetz reblogged this · 6 years ago

milydiadeetz reblogged this · 6 years ago -

secret-student-claire-blog reblogged this · 6 years ago

secret-student-claire-blog reblogged this · 6 years ago -

oggstacy liked this · 7 years ago

oggstacy liked this · 7 years ago -

jaynereads liked this · 7 years ago

jaynereads liked this · 7 years ago -

beautyandthebondage liked this · 7 years ago

beautyandthebondage liked this · 7 years ago -

chaossaphique liked this · 8 years ago

chaossaphique liked this · 8 years ago -

aimeereadsalot liked this · 8 years ago

aimeereadsalot liked this · 8 years ago -

odinscrown liked this · 8 years ago

odinscrown liked this · 8 years ago -

japenglipurlara liked this · 8 years ago

japenglipurlara liked this · 8 years ago -

bookcredentials reblogged this · 8 years ago

bookcredentials reblogged this · 8 years ago -

sunlitstories reblogged this · 8 years ago

sunlitstories reblogged this · 8 years ago -

sunlitstories liked this · 8 years ago

sunlitstories liked this · 8 years ago -

quirky-bibliophile reblogged this · 8 years ago

quirky-bibliophile reblogged this · 8 years ago -

book-bane liked this · 8 years ago

book-bane liked this · 8 years ago -

deteriorating-bookaholic reblogged this · 8 years ago

deteriorating-bookaholic reblogged this · 8 years ago -

tranquilityshallbemine liked this · 8 years ago

tranquilityshallbemine liked this · 8 years ago -

wolfie365 reblogged this · 8 years ago

wolfie365 reblogged this · 8 years ago -

wolfie365 liked this · 8 years ago

wolfie365 liked this · 8 years ago -

sassenachstories-blog reblogged this · 8 years ago

sassenachstories-blog reblogged this · 8 years ago -

bookworm-of-camelot reblogged this · 8 years ago

bookworm-of-camelot reblogged this · 8 years ago -

rosesrosemarythyme liked this · 8 years ago

rosesrosemarythyme liked this · 8 years ago -

spookybookdragon reblogged this · 8 years ago

spookybookdragon reblogged this · 8 years ago -

aflutterofthoughts reblogged this · 8 years ago

aflutterofthoughts reblogged this · 8 years ago -

francesandbooks reblogged this · 8 years ago

francesandbooks reblogged this · 8 years ago -

microbookologist reblogged this · 8 years ago

microbookologist reblogged this · 8 years ago -

sunaslover-k liked this · 8 years ago

sunaslover-k liked this · 8 years ago -

spookybookdragon liked this · 8 years ago

spookybookdragon liked this · 8 years ago -

dropsofatmosphere reblogged this · 8 years ago

dropsofatmosphere reblogged this · 8 years ago -

demonbook reblogged this · 8 years ago

demonbook reblogged this · 8 years ago -

pastelchalklove liked this · 8 years ago

pastelchalklove liked this · 8 years ago -

booksandbookmarkers reblogged this · 8 years ago

booksandbookmarkers reblogged this · 8 years ago -

booksandbookmarkers liked this · 8 years ago

booksandbookmarkers liked this · 8 years ago -

bookworm31 liked this · 8 years ago

bookworm31 liked this · 8 years ago -

jffbabtbt-blog liked this · 8 years ago

jffbabtbt-blog liked this · 8 years ago