Speak Like An Aussie. Left In An Australia Travel Book.

Speak like an Aussie. Left in an Australia travel book.

More stuff like this on Facebook | Instagram

More Posts from Youaurendenial and Others

We were not taught this. I am not prepared.

weeeooooweeeoooweeoo here comes the ambulance!!! get outta the way u dinguses the ambulance is coming!

there it goes. i hope the person inside is ok

IVE SEEN HIM YELL AT TRAFFIC A LOT BUT THIS IS THE BEST ONE

learning how to do motion tracking

Getting to Mars: A New Rocket for the Journey

Do you know what the structural backbone is of our new rocket, the Space Launch System? If you answered the core stage, give yourself a double thumbs up! Or better yet, have astronaut Scott Kelly do it!

We’re on a journey to Mars. For bolder missions to deep space, we need a big, powerful rocket like SLS to take astronauts in the Orion spacecraft to places we’ve never gone before. The core stage is a major part of that story, as it will house the fuel and avionics systems that will power and guide the rocket to those new destinations beyond Earth’s orbit. Here’s how:

It’s Big, and It’s Fast.

The core stage will be the largest rocket stage ever built and is under construction right now at our Michoud Assembly Facility in New Orleans. It will stand at 212 feet tall and weigh more than 2.3 million pounds with propellant. That propellant is cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines. In just 8.5 minutes, the core stage will reach Mach 23, which is faster than 17,000 mph!

It’s Smart.

Similar to a car, the rocket needs all the equipment necessary for the “drive” to deep space. The core stage will house the vehicle’s avionics, including flight computers, instrumentation, batteries, power handling, sensors and other electronics. That’s a lot of brain power behind those orange-clad aluminum walls. *Fun fact: Orange is the color of the rocket’s insulation.

It’s a Five-Parter.

The core stage is made up of five parts. Starting from the bottom is the engine section, which will deliver the propellants to the four RS-25 engines. It also will house avionics to steer the engines, and be an attachment point for the two, five-segment solid rocket boosters. The engine section for the first SLS flight has completed welding and is in the final phases of manufacturing at Michoud.

Next up is the liquid hydrogen tank. It will hold 537,000 gallons of liquid hydrogen cooled to -423 degrees Fahrenheit. Right now, engineers are building the tank for the first SLS mission. It will look very similar to the qualification test article that just finished welding at Michoud. That’s an impressive piece of rocket hardware!

The next part of the core stage is the intertank, which will join the propellant tanks. It has to be super strong because it is the attachment point for the boosters and absorbs most of the force when they fire 3.6 million pounds of thrust each. It’s also a “think tank” of sorts, as it holds the SLS avionics and electronics. The intertank is even getting its own test structure at our Marshall Space Flight Center in Huntsville, Alabama.

And then there’s the liquid oxygen tank. It will store 196,000 gallons of liquid oxygen cooled to -297 degrees. If you haven’t done the math, that’s 733,000 gallons of propellant for both tanks, which is enough to fill 63 large tanker trucks. Toot, toot. Beep, beep! A confidence version of the tank has finished welding at Michoud, and it’s impressive. Just ask this guy.

The topper of the core stage is the forward skirt. Funny name, but serious hardware. It’s home to the flight computers, cameras and avionics. The avionics system is being tested right now in a half-ring structure at the Marshall Center.

You can click here for more SLS core stage facts. We’ll continue building, and see you at the launch pad for the first flight of SLS with Orion in 2018!

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

Be inspired

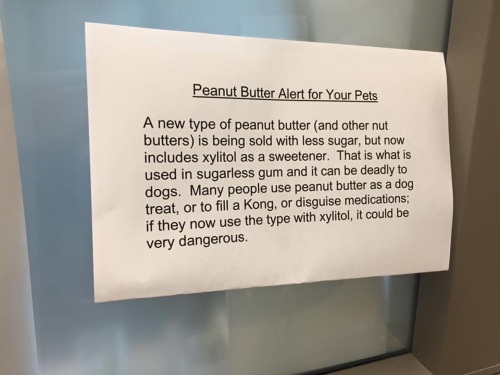

Dog owners please be aware.

do people actually preheat their ovens

-

mazuru7 liked this · 4 months ago

mazuru7 liked this · 4 months ago -

alexthespaceace liked this · 5 months ago

alexthespaceace liked this · 5 months ago -

lu-cid-sky liked this · 1 year ago

lu-cid-sky liked this · 1 year ago -

valkyrie-in-yellow-coat liked this · 2 years ago

valkyrie-in-yellow-coat liked this · 2 years ago -

collamamon liked this · 2 years ago

collamamon liked this · 2 years ago -

blazepandaartz liked this · 2 years ago

blazepandaartz liked this · 2 years ago -

apeartist reblogged this · 2 years ago

apeartist reblogged this · 2 years ago -

apeartist liked this · 2 years ago

apeartist liked this · 2 years ago -

evana-47 reblogged this · 2 years ago

evana-47 reblogged this · 2 years ago -

evana-47 liked this · 2 years ago

evana-47 liked this · 2 years ago -

classic-oi-oi liked this · 3 years ago

classic-oi-oi liked this · 3 years ago -

spectralcider liked this · 4 years ago

spectralcider liked this · 4 years ago -

transboy-taco-bell liked this · 4 years ago

transboy-taco-bell liked this · 4 years ago -

rerarlo liked this · 4 years ago

rerarlo liked this · 4 years ago -

autumn-raptor liked this · 4 years ago

autumn-raptor liked this · 4 years ago -

silentfury-jpg liked this · 4 years ago

silentfury-jpg liked this · 4 years ago -

humble-bee20 liked this · 4 years ago

humble-bee20 liked this · 4 years ago -

gmxforever liked this · 4 years ago

gmxforever liked this · 4 years ago -

elinwindrose liked this · 4 years ago

elinwindrose liked this · 4 years ago -

adjfaghsfdhfahgkshdghgfhh reblogged this · 4 years ago

adjfaghsfdhfahgkshdghgfhh reblogged this · 4 years ago -

grucose liked this · 5 years ago

grucose liked this · 5 years ago -

dorritodoomsday reblogged this · 5 years ago

dorritodoomsday reblogged this · 5 years ago -

originalburningfurniture liked this · 5 years ago

originalburningfurniture liked this · 5 years ago -

grouchomarx86 liked this · 5 years ago

grouchomarx86 liked this · 5 years ago -

varian-polis liked this · 5 years ago

varian-polis liked this · 5 years ago -

gyonyorualomvilag liked this · 5 years ago

gyonyorualomvilag liked this · 5 years ago -

lovelesslionblog liked this · 5 years ago

lovelesslionblog liked this · 5 years ago -

liepas-stuff liked this · 5 years ago

liepas-stuff liked this · 5 years ago -

phantom-of-the-heavymetal-opera liked this · 5 years ago

phantom-of-the-heavymetal-opera liked this · 5 years ago -

spidyspence liked this · 5 years ago

spidyspence liked this · 5 years ago -

zenith-silverlight liked this · 5 years ago

zenith-silverlight liked this · 5 years ago -

amaryllis56-main liked this · 5 years ago

amaryllis56-main liked this · 5 years ago -

kiss-me-sober liked this · 5 years ago

kiss-me-sober liked this · 5 years ago -

steadydogscutehound liked this · 5 years ago

steadydogscutehound liked this · 5 years ago -

5car3b3ar liked this · 5 years ago

5car3b3ar liked this · 5 years ago -

jcash91 liked this · 5 years ago

jcash91 liked this · 5 years ago -

trashbagwithaface liked this · 5 years ago

trashbagwithaface liked this · 5 years ago -

goodnamesweretaken reblogged this · 5 years ago

goodnamesweretaken reblogged this · 5 years ago -

thatblueshyguy liked this · 5 years ago

thatblueshyguy liked this · 5 years ago -

octoberrainposts liked this · 5 years ago

octoberrainposts liked this · 5 years ago -

vaniloves liked this · 5 years ago

vaniloves liked this · 5 years ago -

david-bowie-flowers liked this · 5 years ago

david-bowie-flowers liked this · 5 years ago -

liamismylight reblogged this · 5 years ago

liamismylight reblogged this · 5 years ago -

liamismylight liked this · 5 years ago

liamismylight liked this · 5 years ago -

bowie-star-trekking reblogged this · 5 years ago

bowie-star-trekking reblogged this · 5 years ago